The differentiation and compilation of ball valve models are mainly based on a series of standardized parameters, which together constitute the model identification of ball valves for easy identification, selection, and use. The following is a detailed explanation of the differentiation and compilation methods for ball valve models:

1、 Basic components of ball valve models

Ball valve models typically consist of multiple parameters, including but not limited to: valve type, connection method, material, nominal diameter, nominal pressure, operating mode, etc. By combining these parameters, the model of a ball valve can be uniquely determined.

2、 Specific parameters of ball valve models

Valve type:

There are various structural types of ball valves, such as full pass ball valves, straight through ball valves, three-way ball valves, four-way ball valves, etc. These types are usually represented by the letter Q, followed by specific numbers or letters to indicate the specific type. For example, Q41F represents a full bore ball valve.

Connection method:

The connection methods of ball valves include threaded connection, flange connection, clamp connection, welding connection, etc. These connection methods are commonly represented by specific letters in the model, such as P for flange connection, G for threaded connection, C for clamp connection, etc.

Texture of material:

The material of a ball valve has a significant impact on its performance and usage. Common materials include stainless steel, carbon steel, cast iron, copper, etc. Materials are usually represented by a combination of letters and numbers in models, such as S for stainless steel, WCB for carbon steel, etc.

Nominal diameter (DN):

The nominal diameter of a ball valve is an important parameter indicating the size of the valve, and standard international size standards such as DN15, DN50, DN100, etc. are usually used. This parameter directly represents the diameter of the ball valve in the model.

Nominal pressure (PN):

The nominal pressure of a ball valve is an important parameter indicating the pressure bearing capacity of the valve, and standard international pressure rating standards such as PN10, PN16, PN25, etc. are usually used. This parameter is used in the model to distinguish ball valves with different pressure bearing capacities.

Operation method:

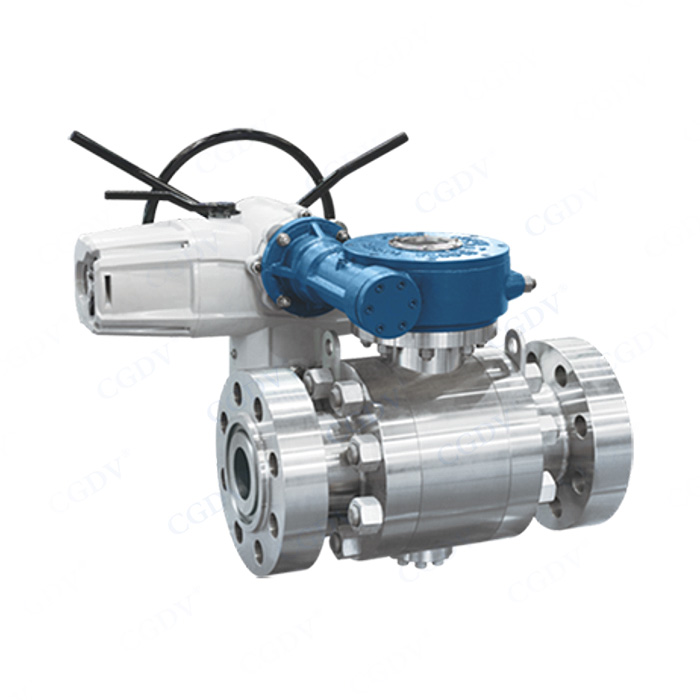

There are various operating modes for ball valves, including manual, pneumatic, and electric. These operation methods are usually represented by specific letters or numbers in the model for differentiation.

3、 Method for compiling ball valve models

The preparation method of ball valve models usually follows certain industry standards and specifications to ensure the accuracy and universality of the models. During the preparation process, it is necessary to combine and label the ball valves according to the specified format and rules based on their actual parameters and purposes.

4、 Example

Taking a certain model of stainless steel flange ball valve as an example, its model may be "Q41F-16P DN100". In this model:

Q41F represents a full bore ball valve;

16P represents a nominal pressure of PN16 and is made of stainless steel (where P may indicate a specific material or standard of stainless steel);

DN100 represents a nominal diameter of 100mm.

5、 Summary

The differentiation and compilation of ball valve models are based on a combination and identification of a series of standardized parameters. By understanding the meanings and programming methods of these parameters, it is easy to identify, select, and use ball valves. In practical applications, it is also necessary to select appropriate ball valve models and parameters based on specific needs and scenarios.

中文

中文 English

English Россия

Россия